Modbus/TCP is an adaptation of the serial

Modbus protocol for TCP/IP communication. The Modbus/TCP driver

can be used for Modbus/TCP or UNICOS at the same time.

Modbus/TCP is used to read or write data blocks

on PLCs.

UNICOS is a CERN defined extension of Modbus/TCP.

A communication with UNICOS is only possible if necessary programming

is made in the PLC (see UNICOS,

basics).

The information exchange takes place via different

function codes (see Modbus/TCP

driver details). These function codes are part of the peripheral

address and have to be specified by the user.

Addressing

The peripheral address includes the following

points:

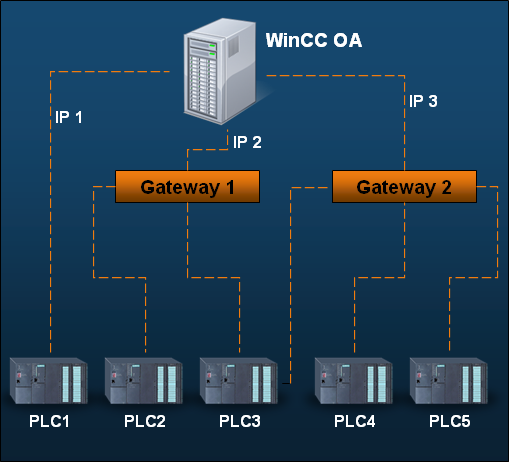

A unit address is required if several PLCs

hang on one LAN-Gateway with an IP address (e.g. for PLC 2 and

PLC 3). If the PLC has an own IP address the unit address should

be set to 1 - e.g. for PLC 1 (see Configuration

panel of the Modbus/TCP driver).

Since a PLC can be reached via several connections

more than one TCP/IP connection can be assigned to one PLC. Maximal

two connections to a PLC are supported. This means that two network

paths are possible.

Master/Slave and Client/Server

The Modbus protocol is based on a master/slave

topology. A master is the unit which initiates a bus transaction

(request) in the communication. The master sends the requests

and the slave responds to the requests. The slave may not send

requests. A slave can never become active. In a TCP/IP environment

the TCP client has to be the master since the client establishes

the connection. The TCP server is the slave. The slave makes a

"Listening Socket" and is able to respond to the connection

requests and further to the requests via this socket.

The driver can both modes (master and slave) at

the same time. The slave modus is needed to receive spontaneous

data, the master mode to send commands and requests (this means

that the driver establishes a connection with the periphery when

it wants to send or request values. The driver also opens a TCP

server socket at the same time. The socket allows the peripheral

devices to connect to the driver and send data spontaneously.)

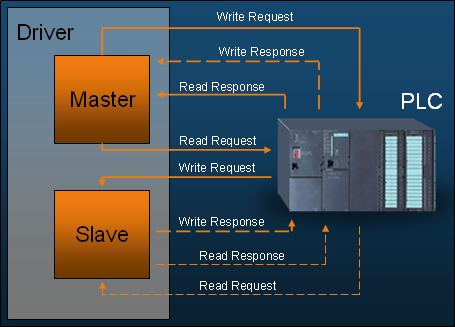

The following figure shows the data flow for a

Modbus/TCP driver:

The master of the driver has to send a write request

in order to send data to the PLC. The response of the write request

is only relevant for the protocol layer. This is shown as dashed

lines in the figure above.

There are two possibilities for input data: the

master either sends a read request in order to query data from

the PLC or the slave receives a write request from the PLC.

The slave responds to the read request with "dummy"

data for simulation purposes. The query of meaningful data from

the driver is not supported because the WinCC OA

does not normally query the PLC data. |