The relevant differences between S7 and S5 PLCs

concerning the WinCC OA

drivers are:

Requirements

In order to communicate with a Siemens S5 PLC via

TCP/IP either a CP1430-TCP or a S5Lan Adapter from ”Process

Informatik” (www.process-informatik.de) is required. The

S5Lan adapter is plugged directly into the S5 programming interface.

CAUTION CAUTION

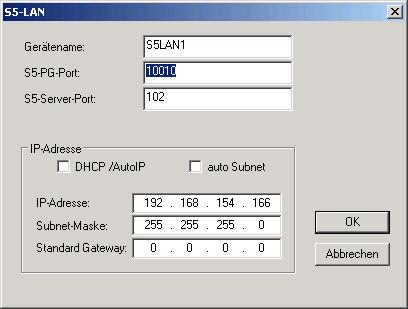

Note that the S5 server port of the S5 LAN manager

ALWAYS has to be set to 102 (See figure below).

Figure: S5 LAN manager

Configuration

The S5 specific entries and the handling of the

internal data point _S7_Config are described in this section.

For the S5 connection, the new configuration is described in the

following table:

Information |

Type |

Send Local TSAP |

string |

Send Remote TSAP |

string |

Receive Local TSAP |

string |

Receive Remote TSAP |

string |

|

These are the TSAPs that must match the settings

in the S5 PLC. For the communication via a S5Lan adapter these

settings can contain arbitrary values.

Figure: Panel for configuration

of a connection to a Siemens S5 PLC

Information on the internal DPE

The Rack, Slot and the TSPPExtras DPEs are not

used for the S5 communication. The information of the S5 connection

is contained in the ConnectionType DPE of the _S7_Config DPT.

For a S5 connection the value must be 256 (the bit 8 has to be

set to one).

The new TSAP elements are combined into a string

DPE s5TSAPs in the form:

”<SendLocalTSAP>.<SendRemoteTSAP>.<ReceiveLocalTSAP>.<ReceiveRemoteTSAP>”

Each TSAP string can contain maximum 8 characters.

Addressing differences between the S7 and S5 PLC

Data Block Organization

The difference between S5 and S7 address layout

is that the data block (DB) addresses are 16bit word based, on

the contrary to the S7 equipment, that is byte based. There are

also some differences in the syntax of the addresses (see table

below). This is relevant for the address selection in the address

panel. The bit number in a DB address e.g. does not run from 0

to 7 but from 0 to 15.

Table: S7 and S7 PLC addresses

S7-300

/ S7-400 variable (corresponds to the address in the para

panel) |

S5

variable (corresponds to the address in the para panel) |

Type

of exchange |

WinCC OA transformation

type |

My.z |

My.z |

read

/ write bits |

boolean |

DBx.DBXy.z |

DBx.Dy.z |

read

/ write bits1 |

boolean |

E(I)y.z |

E(I)y.z |

read

input bits |

boolean |

A(Q)y.z |

A(Q)y.z |

read

/ write output bits1 |

boolean |

MBy |

MBy |

read

/ write bytes |

byte |

DBx.DBBy |

not allowed |

read

/ write bytes |

byte |

E(I)By |

E(I)By |

read

input bytes |

byte |

A(Q)By |

A(Q)By |

read

/ write output bytes |

byte |

MWy |

MWy |

read

/ write words |

int 16/uint 16 |

DBx.DBWy |

DBx.DWy |

read

/ write words |

int 16/uint 16 |

E(I)Wy |

E(I)Wy |

read

input words |

int 16/uint 16 |

A(Q)Wy |

A(Q)Wy |

read

/ write output words |

int 16/uint 16 |

MDy |

MDy |

read

/ write double words |

int 32/uint 32 |

DBx.DBDy |

DBx.DDy |

read

/ write double words |

int 32/uint 32 |

MDyF |

MDyF |

read

/ write floating words |

float |

DBx.DBDyF |

DBx.DDyF |

read

/ write floating words |

float |

Tn |

Tn |

read

/ write timers |

uint 16 |

Zn |

Zn |

read

/ write counters |

uint 16 |

|

The S5 PLC cannot access individual bits. This

means that the writing of individual bits is not possible and

an error message is shown.

Limitations for S5 Support

The following limitations are valid for the communication

to S5 PLCs via the WinCC OA

native S7 driver:

No TSPP is supported for

the S5 equipment. Only one connection for

reading and writing is established to the S5 PLC (i.e. useConnections

config entry is not concerned). Reading of the PLC Time,

PLC operation state and the time synchronisation of the PLC

is not supported. No symbolic addressing is

supported for S5 PLC. Addressing of arrays through

a basic address on the node is not supported.

Example for S5 Configuration using CP1430TCP

Figure: WinCC OA

S5 configuration when using CP1430TCP

|